Green silicon carbide grain size sand

Time:2022-7-14 15:57:50

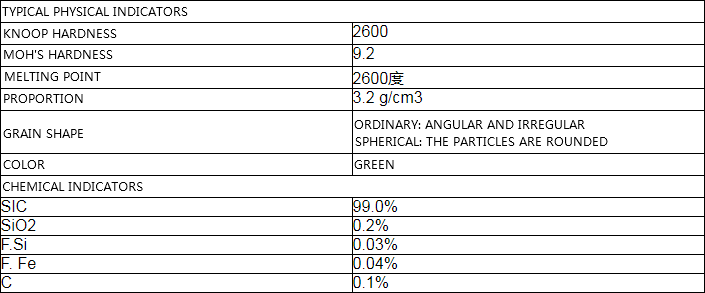

Green silicon carbide is made of petroleum coke and high-quality silica as the main raw materials, adding salt as an additive, and smelted at high temperature in a resistance furnace. It is green crystal, brittle and sharp, and has certain thermal conductivity and electrical conductivity. The microscopic shape is hexagonal crystal, the Mohs hardness of silicon carbide is 9.3, the micro-density hardness is 2940-3300kg/mm2, and the Knoop hardness is 2670-2815kg/mm2, which is higher than corundum in abrasives and second only to diamond and cubic nitride. Boron and Boron Carbide. The density is generally considered to be 3.20-3.25g/cm3. The natural bulk density of silicon carbide abrasives is between 1.2--1.6g/cm3, and the specific gravity is 3.20-3.25g/cm3

Product model and use

1. Granular sand

16#, 20#, 22#, 24#, 30#, 36#, 40#, 46#, 54#, 60#, 70#, 80#, 90#, 100#, 120#, 150#, 180# , 220#, 240#.

Green silicon carbide grain size sand is mainly used for sandblasting media for abrasive tool manufacturing and surface treatment.

Abrasive tool manufacturing: resin grinding wheel, ultra-thin cutting disc, marble grinding wheel, diamond grinding disc, etc.

Surface treatment: grinding carbide, hard and brittle metals and non-metallic materials - quartz glass, optical glass, piezoelectric ceramics, etc.

2. Micro powder

JIS240#, 280#, 320#, 360#, 400#, 500#, 600#, 700#, 800#, 1000#, 1200#, 1500#, 2000#, 3000#, 4000#, 6000#, 8000# , 10000#.

Green silicon carbide powder can be used for precision grinding of hard glass, slicing of single crystal silicon and polycrystalline silicon rods, precision grinding of single crystal silicon wafers, processing of superhard metals, processing of soft metals such as copper and copper alloys, and various resins processing of materials, etc.

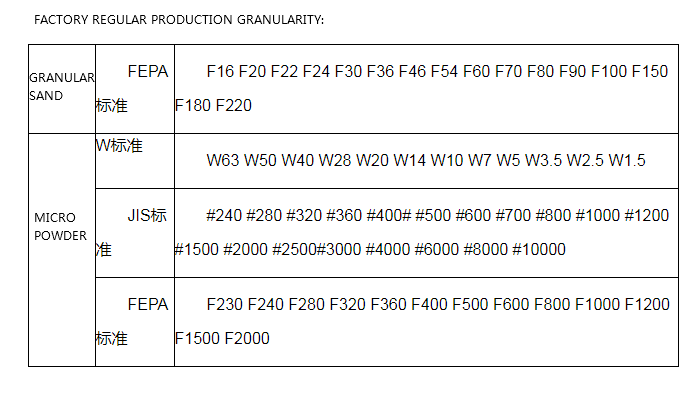

Factory conventional production particle size: particle size sand FEPA standard

F16 F20 F22 F24 F30 F36 F46 F54 F60 F70 F80 F90 F100 F150 F180 F220

Micro powder

W standard

W63 W50 W40 W28 W20 W14 W10 W7 W5 W3.5 W2.5 W1.5

JIS standard

#240 #280 #320 #360 #400# #500 #600 #700 #800 #1000 #1200 #1500 #2000 #2500#3000 #4000 #6000 #8000 #10000

FEPA standard

F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000

The current position:

The current position: