Black silicon carbide powder

Time:2022-7-14 15:52:57

Baotong Company adopts dry method, wet method and combination of dry and wet method to produce silicon carbide micropowder, which is suitable for different needs of different products. The products are mainly used in the manufacture of coated abrasives, bonded abrasives, refractory products, foam ceramic industry, ceramic reaction sintering, solar wafer cutting, crystal crystal cutting and grinding, automobile engine parts manufacturing, special coatings industry, rubber and plastics Product modification, desulfurization, power supply, environmental protection industry and other fields.

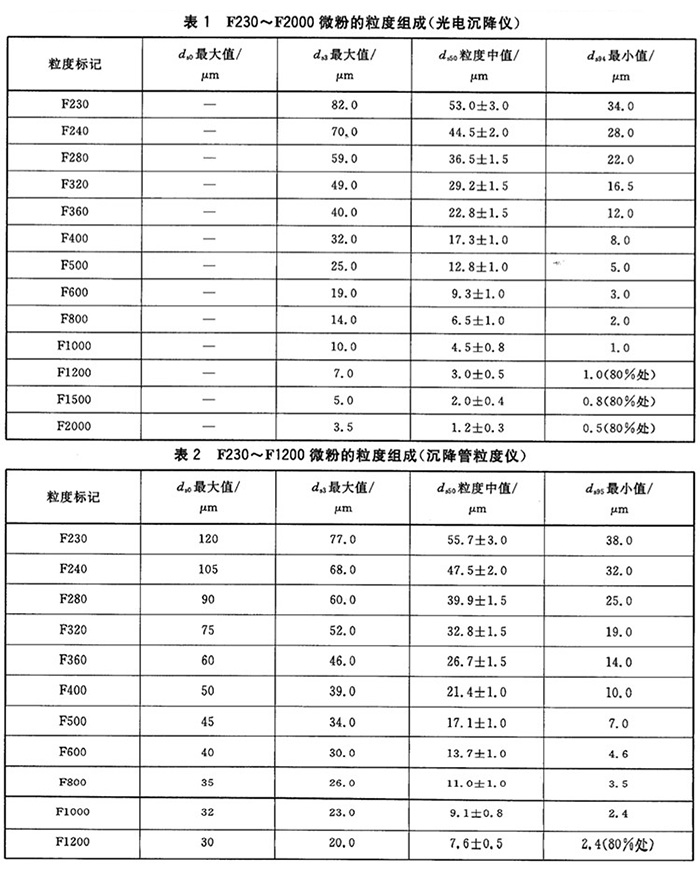

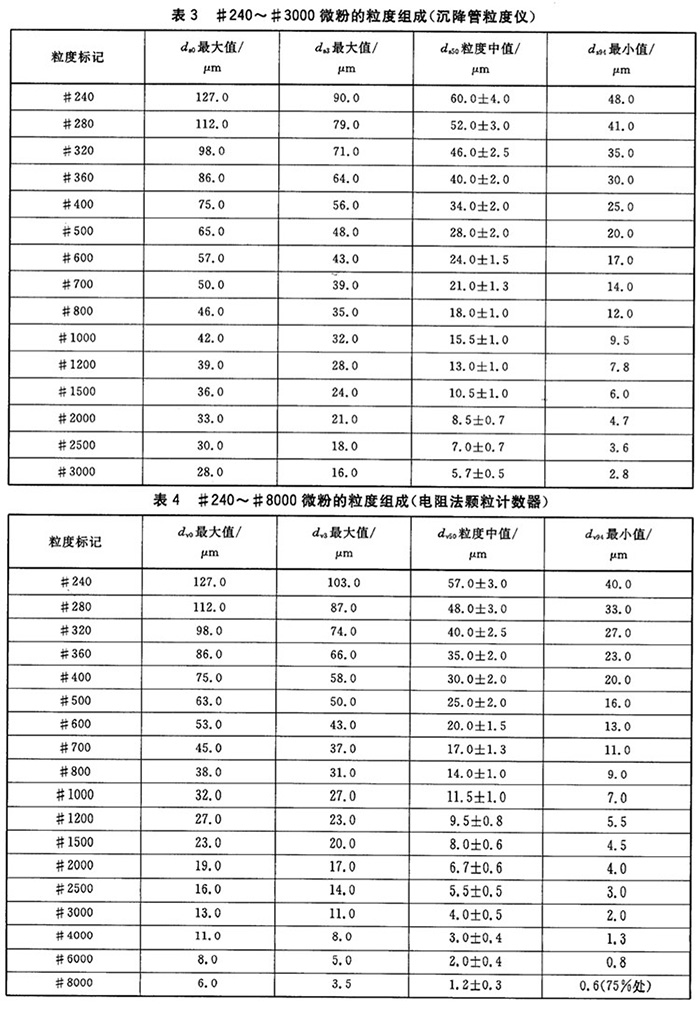

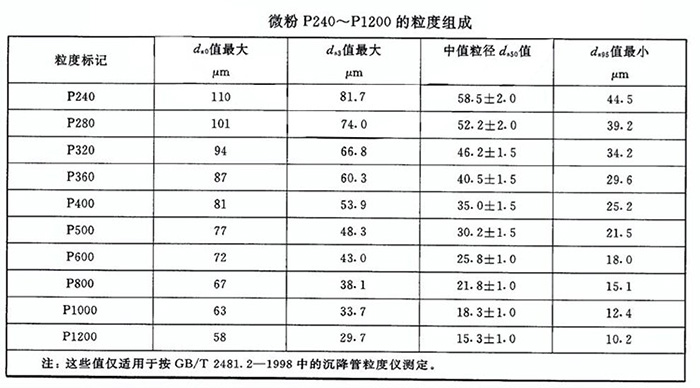

Production process: The black silicon carbide micropowder produced by Baotong refers to the 100UM fine silicon carbide product formed by grinding the original silicon carbide block by Raymond mill, jet mill, ball mill and shaping machine, and then graded by overflow method. Micropowder products of different international standards.

Product features: Silicon carbide has high purity, low impurity content, high particle surface cleanliness, and particle size clusters.

The application range of black silicon carbide micropowder is getting wider and wider, and the demand is further increasing. Baotong Silicon Carbide New Material Co., Ltd. has successfully applied powder negative pressure conveying equipment to the production of silicon carbide micropowder. The price and cost of silicon carbide are reduced and the output is increased. The vacuum feeder uses negative pressure to transport materials. Compared with traditional equipment, the dust during transportation is greatly reduced, which is conducive to improving the production environment of black silicon carbide micropowder.

Previous:

Green silicon carbide powder

The current position:

The current position: